|

|

Rectangular Linear Vibration Motors (LRA’s) |

|

|

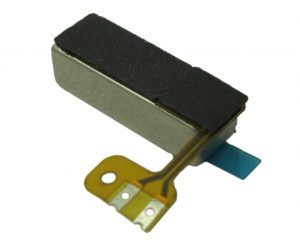

Due to their fast rise and fall times linear resonant actuators (LRA) vibration motors are an excellent choice for haptic feedback applications. The Rise and Fall times listed can be greatly improved by using a Haptic Driver IC which will overdrive the LRA upon start up and apply a 180 degree phase shifted wave form to quickly brake the LRA . Their relatively simple internal construction also offers high reliability and exceptionally long life when compared with brushed ERM motors. The fact that, unlike ERM vibration motors, they have no external moving parts facilitate mounting. It should be noted that none of these types motors is available in a reflow solderable SMD version because they can not survive the high heat of the reflow process. Vybronics’s rectangular LRA’s have an internal mass that oscillates back and forth along the X-axis at its resonant frequency. LRA VIDEO In Hi-Rel applications, they are a viable alternative to brushless vibration motors as the only internal parts that are subjected to wear / failure are the springs. If none of our LRA’s below meets your requirements, if your annual usage is 100K + pcs, we can design and manufacture it for you. |

||

| Part Number |

Old P/N (see PCN) | Image  |

Motor Size (mm) | Voltage (Vac RMS) | Current (mA) |

Response Time (ms) - 50% of power - w/o Haptic Driver |

Res. Freq (hz) | Vibe Force (Grms) | CLICK to BUY from  |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | Rated | Operating | Rated MAX |

Typical* Avg. |

Rise Time |

Fall Time |

||||||

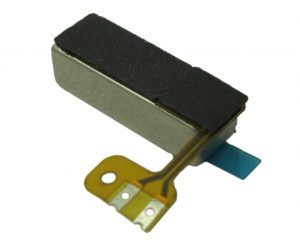

| VL120628H | L120628H |

|

12.0 | 6.0 | 2.8 | 2.0 | 1.0 ~ 2.05 | 130 | 105 | 40 | 60 | 200 | 1.80 | |

| VL181206-160H |

|

18.0 | 12.0 | 6.0 | 2.0 | 0.9 ~ 2.2 | 230 | 191 | 50 | 80 | 160 | 2.30 |

|

|

| VL32158H-L25 |

|

32.0 | 15.0 | 8.0 | 2.0 | 1.5 ~ 2.3 | 300 | 270 | 50 | 120 | 100 | 5.00 | ||

| VL91022-160-320H | L91022-160-320H |

|

22.6 | 10.0 | 9.0 | 1.5 | 0.1 ~ 1.65 | 180 | 155 | 50 | 60 | 160 / 320 | 3.00 | |

| VL91022-170H | L91022-170H |

|

22.6 | 10.0 | 9.0 | 1.5 | 1.2 ~ 1.8 | 180 | 155 | 50 | 60 | 170 | 2.60 |

|

|

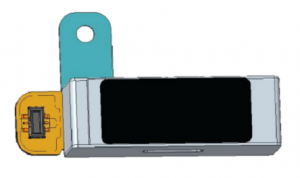

VLV031245-FP418 |

|

12.0 | 4.5 | 3.0 | 1.8 | 0.1 ~ 1.85 | 100 | 60 | 50 | 50 | 240 | 1.00 |

|

|

|

VLV041035L-FP249 |

|

10.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 251 | 1.40 |

|

|

| VLV041235L |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 | ||

| VLV041235L-FP192 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

| VLV041235L-FP235 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

| VLV041235L-FP255 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

|

VLV041235L-FP421 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

| VLV041235L-L20 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 | ||

| VLV041235L-L20-TG3 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

|

VLV041455L-FP409 |

|

14.0 | 4.0 | 5.5 | 1.4 | 0.1 ~ 1.45 | 140 | 47 | 50 | 50 | 180 | 1.90 |

|

|

| VLV101040A | LV101040A |

|

10.0 | 10.0 | 4.0 | 2.5 | 0.1 ~ 2.5 | 350 | 317 | 10 | 40 | 170 | 2.75 | |

| VLV101040J-TG3 |

|

10.0 | 10.0 | 4.05 | 1.0 | 0.1 ~ 1.05 | 150 | 117 | 15 | 60 | 190 | 2.50 |

|

|

|

VLV152564W-80H |

|

14.6 | 24.8 | 6.4 | 1.4 | 0.1 ~ 1.45 | 150 | 70 | 40 | 40 | 80 | 1.00 |

|

|

| VLV200634A |

|

20.0 | 6.0 | 3.43 | 1.5 | 0.1 ~ 1.5 | 215 | 184 | 22 | 60 | 160 | 2.40 | ||

| VLV231372-180H |

|

22.6 | 13.0 | 7.2 | 2.0 | 0.1 ~ 2.0 | 160 | 155 | 50 | 80 | 180 | 3.00 |

|

|

|

VLV281813-65H |

|

28.0 | 18.0 | 13.0 | 2.0 | 0.1 ~ 2.10 | 300 | 110 | 40 | 60 | 65 | 4.80 |

|

|

| VLV281862-65H | 26.0 | 17.8 | 6.2 | 2.83 | 0.1 ~ 6.0 | 240 | 120 | 50 | 80 | 65 | 2.50 |

|

||

| Part Number | Old P/N (see PCN) | Image | L (mm) | W (mm) | H (mm) | Rated (Vac) | Operating (Vac) | Rated MAX (mA) | Typical* (mA) | Rise Time (ms) | Fall Time (ms) | Res. Freq (hz) | Vibe Force (Grms) | BUY SAMPLES HERE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VL120628H | L120628H |

|

12.0 | 6.0 | 2.8 | 2.0 | 1.0 ~ 2.05 | 130 | 105 | 40 | 60 | 200 | 1.80 | |

| VL181206-160H |

|

18.0 | 12.0 | 6.0 | 2.0 | 0.9 ~ 2.2 | 230 | 191 | 50 | 80 | 160 | 2.30 |

|

|

| VL32158H-L25 |

|

32.0 | 15.0 | 8.0 | 2.0 | 1.5 ~ 2.3 | 300 | 270 | 50 | 120 | 100 | 5.00 | ||

| VL91022-160-320H | L91022-160-320H |

|

22.6 | 10.0 | 9.0 | 1.5 | 0.1 ~ 1.65 | 180 | 155 | 50 | 60 | 160 / 320 | 3.00 | |

| VL91022-170H | L91022-170H |

|

22.6 | 10.0 | 9.0 | 1.5 | 1.2 ~ 1.8 | 180 | 155 | 50 | 60 | 170 | 2.60 |

|

|

VLV031245-FP418 |

|

12.0 | 4.5 | 3.0 | 1.8 | 0.1 ~ 1.85 | 100 | 60 | 50 | 50 | 240 | 1.00 |

|

|

|

VLV041035L-FP249 |

|

10.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 251 | 1.40 |

|

|

| VLV041235L |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 | ||

| VLV041235L-FP192 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

| VLV041235L-FP235 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

| VLV041235L-FP255 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

|

VLV041235L-FP421 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

| VLV041235L-L20 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 | ||

| VLV041235L-L20-TG3 |

|

12.0 | 4.0 | 3.5 | 1.8 | 0.1 ~ 1.85 | 60 | 47 | 40 | 60 | 240 | 1.60 |

|

|

|

VLV041455L-FP409 |

|

14.0 | 4.0 | 5.5 | 1.4 | 0.1 ~ 1.45 | 140 | 47 | 50 | 50 | 180 | 1.90 |

|

|

| VLV101040A | LV101040A |

|

10.0 | 10.0 | 4.0 | 2.5 | 0.1 ~ 2.5 | 350 | 317 | 10 | 40 | 170 | 2.75 | |

| VLV101040J-TG3 |

|

10.0 | 10.0 | 4.05 | 1.0 | 0.1 ~ 1.05 | 150 | 117 | 15 | 60 | 190 | 2.50 |

|

|

|

VLV152564W-80H |

|

14.6 | 24.8 | 6.4 | 1.4 | 0.1 ~ 1.45 | 150 | 70 | 40 | 40 | 80 | 1.00 |

|

|

| VLV200634A |

|

20.0 | 6.0 | 3.43 | 1.5 | 0.1 ~ 1.5 | 215 | 184 | 22 | 60 | 160 | 2.40 | ||

| VLV231372-180H |

|

22.6 | 13.0 | 7.2 | 2.0 | 0.1 ~ 2.0 | 160 | 155 | 50 | 80 | 180 | 3.00 |

|

|

|

VLV281813-65H |

|

28.0 | 18.0 | 13.0 | 2.0 | 0.1 ~ 2.10 | 300 | 110 | 40 | 60 | 65 | 4.80 |

|

|

| VLV281862-65H | 26.0 | 17.8 | 6.2 | 2.83 | 0.1 ~ 6.0 | 240 | 120 | 50 | 80 | 65 | 2.50 |

|

NOTES:

- Custom wire length are available for MOQ: 2K pcs

- We can add connectors for MOQ: 2K pcs

- Custom FPC’s are available for MOQ: 5K pcs.

- Tooling and design fees will apply for custom FPC’s ( typical cost ~ USD 2000 )

When compared to standard brushed ERM vibration motors, LRA’s are higher in price and must be used with an external driver IC which are used to produce the AC drive signal required by the LRA. For optimal performance, the AC drive signal should be a the resonant frequency of the LRA. Some LRA drivers have an auto-track feature which will determine the exact resonant frequency of the device it is driving. Since many LRA’s have a very narrow bandwidth, and the resonant frequency might vary slightly from LRA to LRA, it is important to use this auto-tracking feature to achieve optimal performance. The LRA driver is connected to a serial port of a micro-controller which is used to configure the IC driver.

LRA haptic driver IC’s can also improve the rise and fall times of an LRA by briefly overdriving the LRA on start-up, and applying a reverse polarity braking signal when discontinuing the drive signal. Fast rise and fall times are critical for optimal haptic feedback performance.

A number of companies make Haptic IC drivers that are compatible with our linear vibration motors.

Renesas (formerly Dialog Semiconductor) makes a full line of Haptic Drivers as well as an evaluation board that incorporates their popular DA728x Series Haptic driver IC which may be purchased here. Configuration files are available for our most popular LRAs. These files will aid engineers in quickly setting up the DA728x series for optimal performance.

Texas Instruments makes the DRV26xxx series of Haptic Driver and supplies an evaluation board that incorporates the TI DRV2605L haptic driver IC. An alternate version that can drive up to 8 LRA’s is here.

Haptic Labs also makes a unique “No Coding” development toolkit that will aid engineers in developing haptic interactions.

Most LRA’s have a narrow bandwidth / Hi-Q , and applying a frequency above or below the resonant frequency of the LRA will result in the LRA producing a lower vibration amplitude or if far from the resonant frequency, none at all.

Newer generations of LRAs, like the VLV152564W have a resonant frequency of 80 hz, but have a wide-band width, and are usable when into the audio frequency range. Please consult the frequency response curves in the data sheets to explore a devices usable bandwidth.