|

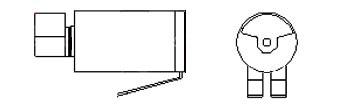

Spring Contact Vibration Motors |

|

|

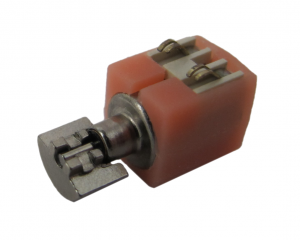

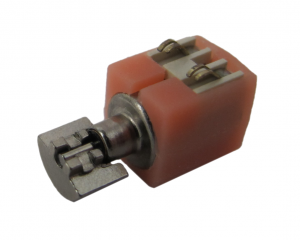

This series of surface mount vibration motors, with spring contacts, make an excellent choice for a variety of reasons. Unlike our SMT Reflow motors, these motors are NOT designed to be soldered to the PCB. The contact springs on these motors simply mate with contact pads on the PCB. This type of motor offers some distinct advantages as follows: Lower Cost: This series of motors are approx. 10% lower in cost than SMT reflow vibration motors. CLICK HERE to see photos of motors mounted in devices. CLICK HERE to see how to properly remove these from packing trays |

||

| Part Number |

Old P/N (see PCN) | Image  |

Config. Type | Motor Size (mm) | Voltage (Vdc) | Current (mA) | Rated speed (rpm) | Rated Vibe Freq. (Hz) | Vibe Force (Grms) | CLICK to BUY from  |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia / Hgt | Body Length |

Overall Length |

Rated | Operating | Rated MAX |

Typical* Avg. |

||||||||

| VZ3TH5B0640081P |

|

5 | 3.2 / 4.2 | 8.4 | 12.3 | 3.0 | 2.5~3.6 | 80 | 67 | 10500 | 175 | 0.75 |

|

|

| VZ3TH5B3120066P |

|

5 | 3.2 / 4.2 | 8.4 | 13.1 | 3.0 | 2.5~3.6 | 40 | 27 | 12000 | 200 | 0.60 |

|

|

|

VZ3TH5B3120076P |

|

5 | 3.2 / 4.2 | 8.4 | 13.1 | 3.0 | 2.5~3.6 | 16 | 12 | 8500 | 142 | 0.50 | ||

| VZ3TH8B171700L | Z3TH8B171700L |

|

5 | 2.5 / 2.9 | 6.6 | 11.0 | 2.7 | 2.3~3.3 | 100 | 77 | 13000 | 217 | 0.40 | |

| VZ4KH1A0031121 | Z4KH1A0031121 |

|

5 | 4.0 / 5.9 | 11.4 | 16.6 | 1.3 | 1.1~1.6 | 85 | 57 | 8500 | 142 | 0.85 |

|

| VZ4KH2B0470653N | Z4KH2B0470653N |

|

5 | 4.0 / 5.95 | 11.4 | 16.2 | 3.0 | 2.2~3.6 | 75 | 56 | 11000 | 183 | 1.55 | |

| VZ4SH2B0071097N | 5 | 4.0 / 5.8 | 10.4 | 14.7 | 3.0 | 2.2~3.6 | 70 | 45 | 10000 | 167 | 1.25 |

|

||

| VZ4TC2B0640007P |

|

6 | 4.0 / 5.0 | 5.8 | 9.6 | 3.0 | 2.4~3.6 | 22 | 19 | 8000 | 133 | 0.25 |

|

|

| VZ4TH2B0370078L | Z4TH2B0370078L |

|

5 | 4.0 / 4.5 | 8.6 | 12.3 | 3.0 | 2.4~3.6 | 30 | 20 | 10000 | 167 | 0.70 |

|

| VZ4TH5B0191760L | Z4TH5B0191760L |

|

5 | 4.0 / 4.5 | 8.6 | 11.6 | 3.0 | 2.4~3.6 | 85 | 55 | 14000 | 233 | 0.80 | |

| VZ4TH5B1241993L | Z4TH5B1241993L |

|

5 | 4.0 / 4.9 | 8.7 | 11.9 | 3.0 | 2.4~3.6 | 85 | 55 | 14000 | 233 | 0.80 | |

| VZ4TH5B1462252 | Z4TH5B1462252 |

|

5 | 4.0 / 4.9 | 8.7 | 12.7 | 3.0 | 2.2~3.6 | 30 | 21 | 13000 | 217 | 0.40 |

|

| VZ4TH5B1709181L | Z4TH5B1709181L |

|

5 | 4.0 / 5.5 | 8.9 | 13.4 | 3.0 | 2.4~3.6 | 110 | 84 | 10000 | 167 | 1.10 | |

| VZ4TH5B1762257U |

|

6 | 4.0 / 5.6 | 8.9 | 11.9 | 3.0 | 2.2~3.6 | 15 | 11 | 12000 | 200 | 0.30 |

|

|

| VZ4TH7B2120042P | Z4TH7B2120042P |

|

6 | 4.0 / 5.0 | 8.5 | 12.3 | 3.0 | 2.4~3.6 | 12 | 9 | 8000 | 133 | 0.45 | |

| VZ6CH1A0082352 | Z6CH1A0082352 |

|

5 | 6.0 / 8.05 | 15.3 | 20.8 | 1.3 | 0.9~1.6 | 80 | 67 | 7500 | 125 | 1.10 |

|

| VZ6DH2B1501851 | Z6DH2B1501851 |

|

5 | 6.0 / 7.2 | 13.1 | 17.8 | 3.0 | 2.2~3.6 | 75 | 53 | 11000 | 183 | 1.20 | |

| VZ6DH2B1501852 | Z6DH2B1501852 |

|

5 | 6.0 / 7.2 | 13.1 | 17.8 | 3.0 | 2.0~3.6 | 40 | 23 | 9500 | 158 | 1.00 |

|

| VZ6SH1A0060711 | Z6SH1A0060711 |

|

5 | 6.0 / 8.05 | 10.3 | 14.4 | 1.3 | 0.9~1.6 | 90 | 68 | 8500 | 142 | 0.80 |

|

| VZ6SH1B0060711 | Z6SH1B0060711 |

|

5 | 6.0 / 8.05 | 10.3 | 14.4 | 3.0 | 2.2~3.6 | 70 | 52 | 10000 | 167 | 1.10 | |

| Part Number | Old P/N (see PCN) | Image | Config. Type | Dia / Hgt (mm) | Body L (mm) | Overall L (mm) | Rated (V) | Operating (V) | Rated MAX (mA) | Typical* (mA) | Speed (rpm) | Rated Freq. (Hz) | Vibe Force (Grms) | BUY SAMPLES HERE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VZ3TH5B0640081P |

|

5 | 3.2 / 4.2 | 8.4 | 12.3 | 3.0 | 2.5~3.6 | 80 | 67 | 10500 | 175 | 0.75 |

|

|

| VZ3TH5B3120066P |

|

5 | 3.2 / 4.2 | 8.4 | 13.1 | 3.0 | 2.5~3.6 | 40 | 27 | 12000 | 200 | 0.60 |

|

|

|

VZ3TH5B3120076P |

|

5 | 3.2 / 4.2 | 8.4 | 13.1 | 3.0 | 2.5~3.6 | 16 | 12 | 8500 | 142 | 0.50 | ||

| VZ3TH8B171700L | Z3TH8B171700L |

|

5 | 2.5 / 2.9 | 6.6 | 11.0 | 2.7 | 2.3~3.3 | 100 | 77 | 13000 | 217 | 0.40 | |

| VZ4KH1A0031121 | Z4KH1A0031121 |

|

5 | 4.0 / 5.9 | 11.4 | 16.6 | 1.3 | 1.1~1.6 | 85 | 57 | 8500 | 142 | 0.85 |

|

| VZ4KH2B0470653N | Z4KH2B0470653N |

|

5 | 4.0 / 5.95 | 11.4 | 16.2 | 3.0 | 2.2~3.6 | 75 | 56 | 11000 | 183 | 1.55 | |

| VZ4SH2B0071097N | 5 | 4.0 / 5.8 | 10.4 | 14.7 | 3.0 | 2.2~3.6 | 70 | 45 | 10000 | 167 | 1.25 |

|

||

| VZ4TC2B0640007P |

|

6 | 4.0 / 5.0 | 5.8 | 9.6 | 3.0 | 2.4~3.6 | 22 | 19 | 8000 | 133 | 0.25 |

|

|

| VZ4TH2B0370078L | Z4TH2B0370078L |

|

5 | 4.0 / 4.5 | 8.6 | 12.3 | 3.0 | 2.4~3.6 | 30 | 20 | 10000 | 167 | 0.70 |

|

| VZ4TH5B0191760L | Z4TH5B0191760L |

|

5 | 4.0 / 4.5 | 8.6 | 11.6 | 3.0 | 2.4~3.6 | 85 | 55 | 14000 | 233 | 0.80 | |

| VZ4TH5B1241993L | Z4TH5B1241993L |

|

5 | 4.0 / 4.9 | 8.7 | 11.9 | 3.0 | 2.4~3.6 | 85 | 55 | 14000 | 233 | 0.80 | |

| VZ4TH5B1462252 | Z4TH5B1462252 |

|

5 | 4.0 / 4.9 | 8.7 | 12.7 | 3.0 | 2.2~3.6 | 30 | 21 | 13000 | 217 | 0.40 |

|

| VZ4TH5B1709181L | Z4TH5B1709181L |

|

5 | 4.0 / 5.5 | 8.9 | 13.4 | 3.0 | 2.4~3.6 | 110 | 84 | 10000 | 167 | 1.10 | |

| VZ4TH5B1762257U |

|

6 | 4.0 / 5.6 | 8.9 | 11.9 | 3.0 | 2.2~3.6 | 15 | 11 | 12000 | 200 | 0.30 |

|

|

| VZ4TH7B2120042P | Z4TH7B2120042P |

|

6 | 4.0 / 5.0 | 8.5 | 12.3 | 3.0 | 2.4~3.6 | 12 | 9 | 8000 | 133 | 0.45 | |

| VZ6CH1A0082352 | Z6CH1A0082352 |

|

5 | 6.0 / 8.05 | 15.3 | 20.8 | 1.3 | 0.9~1.6 | 80 | 67 | 7500 | 125 | 1.10 |

|

| VZ6DH2B1501851 | Z6DH2B1501851 |

|

5 | 6.0 / 7.2 | 13.1 | 17.8 | 3.0 | 2.2~3.6 | 75 | 53 | 11000 | 183 | 1.20 | |

| VZ6DH2B1501852 | Z6DH2B1501852 |

|

5 | 6.0 / 7.2 | 13.1 | 17.8 | 3.0 | 2.0~3.6 | 40 | 23 | 9500 | 158 | 1.00 |

|

| VZ6SH1A0060711 | Z6SH1A0060711 |

|

5 | 6.0 / 8.05 | 10.3 | 14.4 | 1.3 | 0.9~1.6 | 90 | 68 | 8500 | 142 | 0.80 |

|

| VZ6SH1B0060711 | Z6SH1B0060711 |

|

5 | 6.0 / 8.05 | 10.3 | 14.4 | 3.0 | 2.2~3.6 | 70 | 52 | 10000 | 167 | 1.10 |

The “typical current” is the average current from 20 motors selected at random from a given production lot. Copies of the test report showing the data collected for all 20 motors are available upon request.

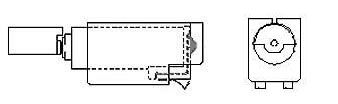

| Config Type 5 COMPRESSION SPRING MOUNT | Config Type 6 COMPRESSION SPRING MOUNT |

|

|

The spring contacts of these vibration motors are not designed to be soldered to. A downward force must but be applied to the top of the motors body to compress the spring contacts directly against corresponding PCB contact pads. It is recommended that these pads be gold plated to improve reliability. Some recommended motor mounting options include, fabricating a silicone rubber pad with a cut out for the motor which will properly locate the motor directly above the PCB pads. Recesses are designed under the pad to accommodate the profiles of all the other parts that lie beneath it. When the product housing is closed, it will exert a downward pressure on the vibrator motor ensuring properly spring compression and electrical contact. Alternately, a pocket may be created in the plastic cover (shell) of the products housing to hold the motor. The motor are mounted in a silicone rubber boot that helps retain the motor in the pocket and helps dampen high frequency harmonics. When the cover is closed, the contacts mate with corresponding pads on the PCB.